Atomic Layer Deposition of Optical Coatings - ALDOC

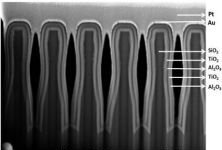

Within the Emmy Noether junior research group, thin film coatings for optical applications will be developed and characterized. Dielectric and metallic functional coatings deposited by atomic layer deposition (ALD) are essential in the development of improved and innovative nanostructured optics. Atomic layer deposition is a powerful coating technology with excellent thickness control, uniformity, and conformal film deposition on high aspect ratio nanostructures. Thermal and plasma enhanced deposition is carried out to obtain optical coatings with best properties. The optical properties derived from in situ and ex situ spectroscopic ellipsometry characterization are applied in the computational design of optical elements.

Optical applications of ALD coatings

- X-ray nanolaminates

- antireflective coatings and interference filters

- diffractive optical elements

- metal wire polarizers

- high efficiency transmission gratings

- metamaterials

- guided mode resonance gratings

The optical functionality of the elements is fine-tuned by ultra-thin, conformal ALD coatings. In situ monitoring is being implemented for the development of such highly demanding optics